about us

Sahand Azin Company

Sahand Azin Company started its activity in 2016 in the field of designing, modeling and manufacturing all kinds of industrial molds, including plastic and matrix mandrels. According to the design, executive and production records of the company’s management in the field of household appliances production, especially household refrigerators and gas stoves, as well as the gaps and needs of domestic production parts, in the first stage of the design and production of aluminum handles with plating coatings Anodize, hard anodize and all kinds of electrostatic powder colors according to the customer’s order.

Production units in Sahand Azin

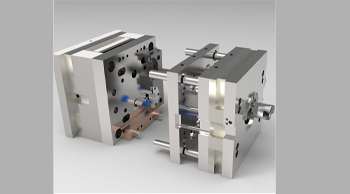

Molding unit

This unit includes the design, modeling and manufacturing of all kinds of industrial molds, including all kinds of plastic, extruded, die cast, mandrel and matrix molds, using the power of an experienced and experienced design and molding team, as well as the presence of modern machines and devices. It has milling, turning, radial drill, spark, CNC milling.

Plastic injection unit

This unit, having injection devices with different capacities from 120 grams to 1200 grams, is producing all kinds of plastic parts for refrigerators, freezers, gas stoves, etc.

Aluminum unit

Given that the production of all kinds of handles for refrigerators, freezers and gas stoves with aluminum material is one of the main primary products of this company, and with a variety of products of more than 15 models of handles in different designs, they are working as general sales, exclusive models, design and Production according to customer’s order is possible.

Sahand Azin in the passage of time

Get to know us more as time passes

Sahand Azin company was founded and started working this year. This group started its work by designing, modeling and manufacturing all kinds of industrial molds, including plastic injection molds and matrix mandrels.

According to the customer's demand and implemented plans, he started the plastic injection unit.

Increasing plastic injection machines and developing the molding department.

Equipping the molding unit and adding a large CNC milling machine and other necessary devices, as well as setting up the aluminum profile finishing unit.

According to the necessity and needs of the company, the installation and operation of the aluminum extrusion unit and also the development of the plastic injection unit took place.

Setting up anodizing and sealing aluminum plating line in various matte, semi-glossy and glossy ranges